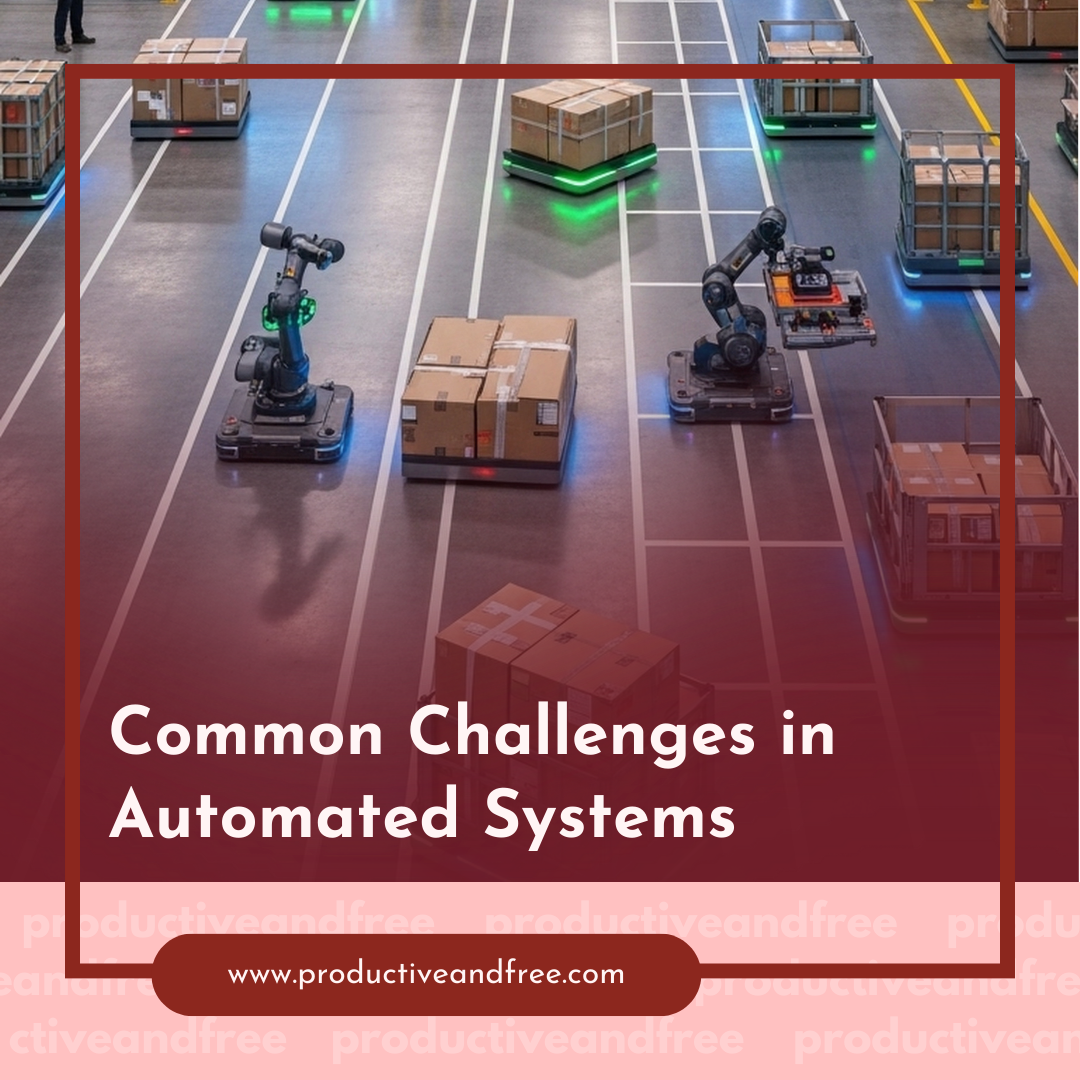

Common Challenges in Automated Systems

Automation has changed industries by streamlining workflows and increasing productivity. Yet like any sophisticated system, automated setups may occasionally experience glitches that impede smooth operations. Some of the time mechanical assemblies are being identified as potential sources of trouble. But many other areas within an automated system could cause issues as well. Anticipating potential hurdles early can ensure optimal performance without costly downtime. In this blog, we will look at some of the areas in which automated systems can experience challenges.

Software Glitches and Programming Errors

Automated systems depend heavily on software to run their operations efficiently. But even minor coding mistakes or incompatibility can wreak havoc, including outdated or incorrect system updates and incorrect parameter settings causing performance disruption. Debugging errors is time consuming yet important in keeping systems operating optimally. Regular audits as well as use of strong testing frameworks can reduce risks significantly.

Mechanical Assemblies

Mechanical assemblies form the physical infrastructure that supports automated systems. Mechanical assemblies consist of components like gears, belts, bearings and actuators working in unison to execute tasks. Challenges associated with these assemblies often come up in terms of wear and tear, misalignments or inadequate lubrication resulting in operational inefficiencies or machinery breakdown. Regular maintenance, precise calibration and using high-quality materials can significantly extend their durability and performance for seamless operation within the automated systems.

Sensor Failures and Calibration Issues

Sensors are like the eyes and ears of an automated system, gathering critical data for operation accuracy. However, poorly calibrated or malfunctioning sensors can provide inaccurate readings that lead to inappropriate responses. For instance temperature sensors in manufacturing setups or motion detectors in robotics may falter under extreme conditions or wear and tear, necessitating frequent calibration checks as well as replacement at or before their lifespan ends for accurate performance.

Communication and Networking Problems

Automated systems nowadays rely heavily on communication protocols for coordination among their components across networks. Signal interference, outdated infrastructure or incompatibilities between communication standards can pose serious obstacles in information flow, particularly problematic for facilities using Industrial Internet of Things (IIoT). Implementing uniform protocols across all components as well as investing in advanced network setups are just some solutions to overcome any roadblocks encountered while networking systems run their course.

Power Supply Instabilities

A stable and consistent power source is important to any automation process, and fluctuations, unexpected outages or insufficient capacity can greatly interfere with automated systems resulting in compromised equipment performance or data loss. Even minor voltage variations have the power to harm crucial components like control units and drives, potentially shortening their lifespan and diminishing the overall system efficiency. Uninterruptible power supplies (UPSs) are very important in protecting against power instabilities, providing backup power during outages while safeguarding against sudden surges that could otherwise destroy equipment.

Conclusion

Automated systems are complex machines that depend on intricate interactions among hardware, software and infrastructure components to function optimally. Mechanical assemblies, software updates, sensors, communication channels and power supply all carry potential for disruptions. But with regular maintenance measures in place these issues can often be preempted and smoothly run systems can protect the long-term investments in automation.

Share in the comments below: Questions go here